In this article, we will trace the advancements in collision repair techniques and historic autobody technology.

The evolution of autobody techniques has been an integral part of the automotive industry since its inception. From traditional methods, such as hammer and dolly work, to modern techniques, such as laser scanning and 3D printing, advances in technology have revolutionized the way auto body repairs are performed. Over the years, countless improvements have been made to streamline the process and help make repairs more effective and efficient.

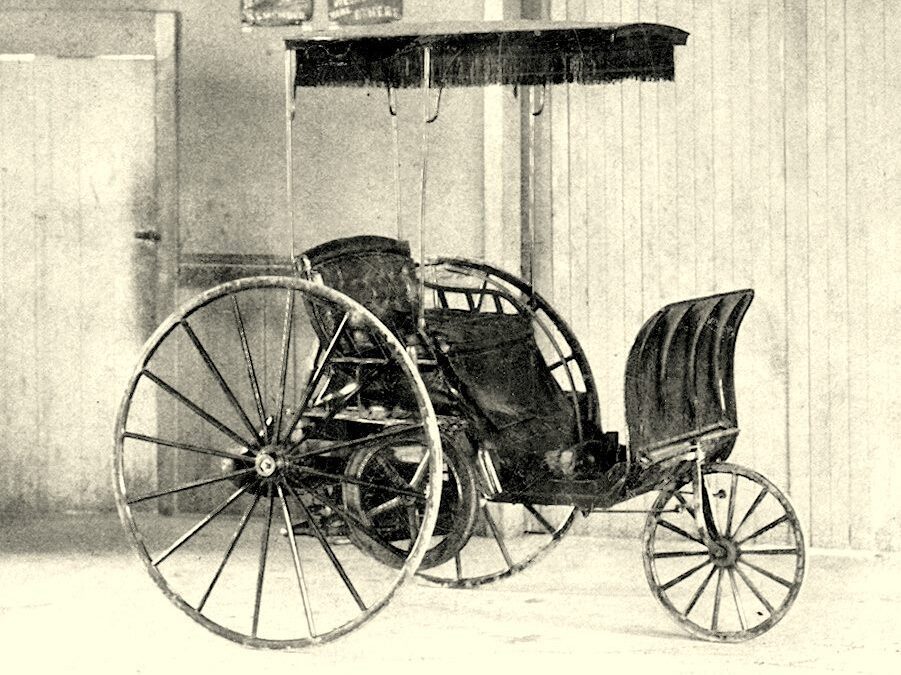

Autobody Repair in History

In the early years, many people turned to a machinist or even a bicycle repair shop for car repairs. As the popularity of the automobile grew, so did the demand for experienced and reliable mechanics and auto body specialists.

A Brief History of Auto Body Repair, via Rustblasters

In the late 19th century, traditional methods used by auto body repair shops relied on the use of basic tools, such as hammers, dollies, and heat guns, to reshape damaged metal. This method was incredibly labor-intensive and often resulted in inaccurate repairs to the automobiles.

In the early days of the car industry, when an automobile, such as a Model T Ford, was involved in a collision or suffered damage to its body, skilled craftsmen had to rely on their experience and craftsmanship to restore the damaged metal to its original form. This process involved the use of basic hand tools like hammers and dollies.

To begin the process, technicians would carefully analyze the extent of the damage and develop a plan of action. They would then use hammers and dollies to reshape the damaged metal, carefully working to restore it to its original form. Heat guns were also used to help manipulate the metal and make it more pliable.

One of the major challenges with traditional autobody repair was the difficulty in achieving precise, consistent results. Because the process relied heavily on the skill and experience of the technician, there was a higher risk of human error and variations in the finished product. Additionally, repairing severely damaged or complex areas, such as curved panels or intricate body lines, posed significant challenges.

Modern Autobody Repair

However, modern techniques have become increasingly more precise and effective with advances in technology.

Computerized measuring systems are now used to make sure that each panel is measured and aligned correctly, eliminating the need for guesswork. Additionally, new materials have been developed to make the work easier and more accurate. These include high-strength steel alloys, aluminum alloys, and plastic composites.

Seemingly, modern cars appear fragile and cheap, as they are designed to crush or collapse by absorbing impact to shield passengers from injury. Thus, modern cars experience more damage than older cars in the event of a collision. But in reality, vehicles absorb crash impact rather than passengers.

Collision Repair Industry Roots, via Liberty Collision Reno

3D printing and laser measurement have become increasingly prominent in autobody repair. Laser scanning is a popular technique that uses lasers to create an accurate, three-dimensional map of the damaged area. This allows auto body specialists to get a better understanding of the extent of the damage and be more precise in diagnosing the damage.

These technologies allow technicians to quickly and accurately reproduce parts with exact measurements and precision. 3D printing can be used to recreate structural components, such as bumpers, grilles, and spoilers.

As autobody techniques continue to evolve, it is clear that technology will play an integral role in the industry. By leveraging cutting-edge tools and materials, collision repair shops can provide their customers with the highest levels of service and ensure a safe and effective fix.

Conclusion

The evolution of collision repair techniques has gone from traditional, labor-intensive methods to modern, efficient, and technologically advanced methods. Today, collision repair technicians have access to a wide variety of incredible tools and processes that enable them to quickly and accurately restore damaged vehicles to their pre-accident condition. This technology not only reduces costs and turnaround times but also increases customer satisfaction.

It’s the goal of Newark Autobody Collision and Glass and Zanesville Autobody Collision and Glass to keep our technicians up-to-date with the latest techniques and certifications to ensure that all our repairs are top quality.

Related Reading:

Ohio Drivers: Contact Zanesville Autobody for Your Paintless Dent Repair

This article was originally published by Zanesville Autobody Collision and Glass, LLC, a member of the Autobody of Ohio family of auto body shops. If you are in Ohio and looking for a quality autobody shop “near me”, we are here to help you. We’ll make your car like new again!

Zanesville Autobody Collision and Glass

1152 Newark Road

Zanesville, Ohio 43701

Phone: (740) 487-3111

Fax: (740) 888-3500